Effective quality control is crucial for operational excellence and increased efficiency, ensuring that products not only meet but often exceed customer expectations. Research by McKinsey indicates that implementing digitally enabled quality controls can lead to cost reductions and increased efficiency ranging from 15-45%.

The overarching goal of quality control is to minimize product defects and maintain consistency. This is achieved by employing various techniques and procedures to monitor, inspect, and regulate production processes.

In manufacturing industries, quality control involves establishing stringent quality standards, conducting regular inspections, and implementing technologies such as sensors, automation, and process control tools for real-time monitoring and optimization.

Manufacturing industries employ statistical methods, including Six Sigma and Statistical Process Control (SPC), to pinpoint and address deviations from desired quality levels. Furthermore, they integrate Quality Management Systems (QMS) to establish comprehensive documentation, corrective actions, and continuous improvement processes.

Whether you are a process engineer, a data scientist, a decision-maker, or a professional in the manufacturing sector, this article will guide your selection of high-quality control software for your industry.

Manufacturing quality control software: types

In manufacturing quality control systems, two dominant types of software are widely used: Statistical Process Control (SPC) and Quality Management Software/System (QMS). Let’s delve into their similarities and differences.

1. Statistical Process Control (SPC)

SPC primarily focuses on monitoring and controlling production processes. It’s concerned with real-time data analysis and ensures that manufacturing processes operate within specified limits while minimizing variations.

SPC aids in the maintenance of consistency and uniformity in the manufacturing process. It helps identify and address issues in real-time, ensuring that products continually meet quality standards.

2. Quality Management Software / System (QMS)

QMS has a broader scope, covering the production process and other aspects of quality control, including document control, compliance management, and overall process optimization. Therefore, QMS is more comprehensive, encompassing elements that go beyond process control.

QMS aims to establish a systematic approach to quality management across the entire organization. It ensures the integration of quality into processes, encompassing risk management, continuous improvement, supplier management, and the inclusion of customer feedback.

This comprehensive approach helps organizations achieve consistent quality, compliance with standards, and customer satisfaction. Some examples of QMS tools are MasterControl and IQMS (now DelmiaWorks).

This article will mainly focus on quality control through process control, as it directly oversees and manages manufacturing processes, ensuring they operate efficiently and consistently. The advantages of quality control through process control, in comparison to Quality Management Systems (QMS), include:

- Immediate issue resolution – Process control detects and addresses issues in real-time, preventing defects before they occur.

- Cost reduction – Process control has a more direct impact on reducing waste and production costs compared to QMS. This is achieved by minimizing process variations and defects.

- Efficiency improvement – Process control improves production efficiency and cycle times by optimizing processes, leading to increased productivity.

- Consistency – Process control ensures consistent product quality, while QMS emphasizes documentation and compliance across various quality-related areas.

- Data-driven improvement – Process control relies on real-time data analysis for continuous process improvement.

Key elements involved in process control are:

- Data monitoring

- Feedback loops

- Statistical analysis

- Automation

- Quality assurance

5 best manufacturing quality control software: A detailed overview

Before going into the top 5 manufacturing quality control software in the market, let's explore the essential criteria to make an informed choice:

- Real-time monitoring – The software should offer real-time monitoring capabilities, allowing you to track critical process parameters as they occur and detect deviations promptly.

- Data collection and analysis – Collect and analyze data from various stages of the manufacturing process, enabling you to identify trends, patterns, and potential issues.

- Statistical Process Control (SPC) – Look for SPC tools that enable statistical analysis and process capability assessments to maintain consistent quality levels.

- Alerts and notifications – The software should provide customizable alerts and notifications to inform operators and managers when process variations or anomalies occur.

- Integration and adaptability – Ensure the software can integrate seamlessly with your existing systems, such as PLCs, SCADA systems, and other manufacturing equipment. The software should also offer customization options to fit your specific manufacturing process and quality standards, making it adaptable.

- Automation – The software should offer features that trigger corrective and predictive action or adjustment based on predefined rules and thresholds.

- Reporting and analytics – Robust reporting and analytics capabilities throughout the product lifecycle should help you gain detailed information about process performance and make data-driven decisions.

1. Basetwo

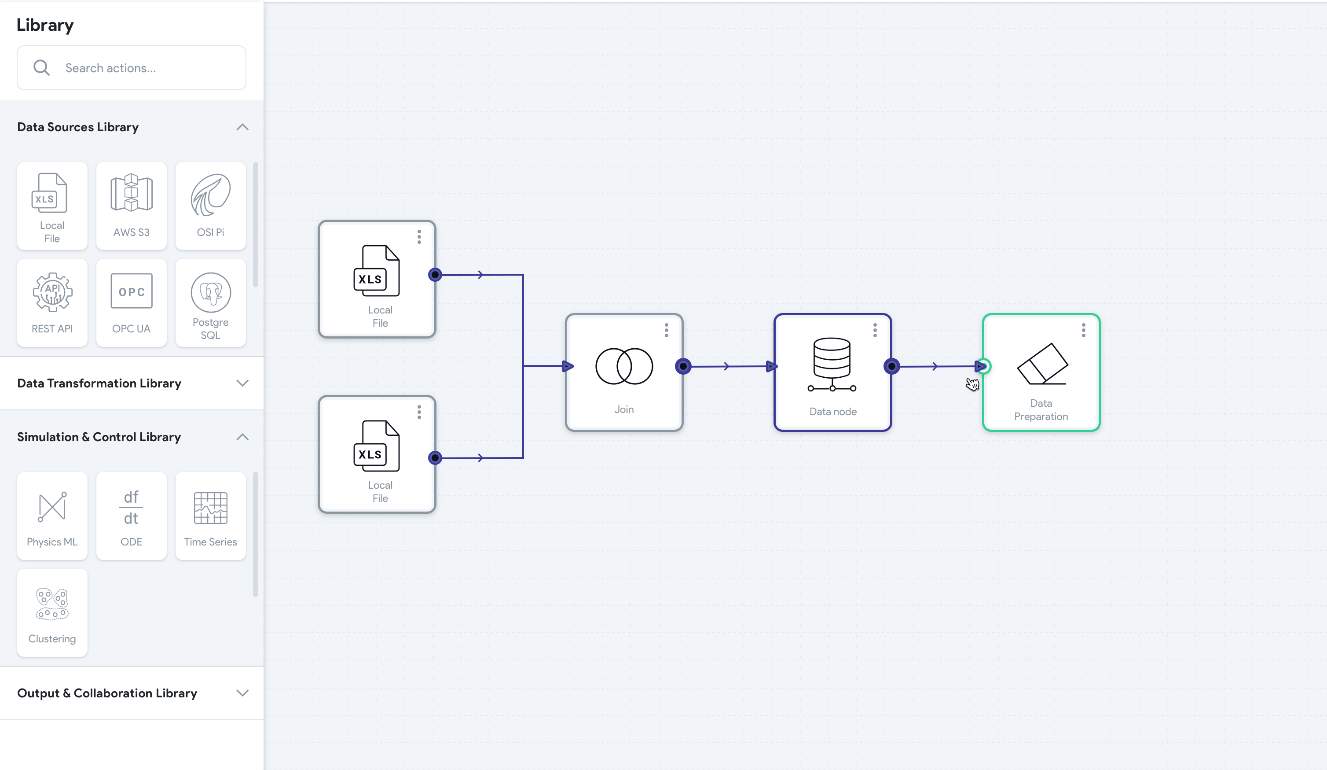

Basetwo is a web-based software solution that provides an AI-powered copilot to help drive optimal process engineering decisions.

Basetwo enables teams to achieve quality control by rapidly deploying digital twins for manufacturing units. These virtual environments mimic the manufacturing process and enhance quality control by providing real-time data, simulations, and analytics.

Usually, implementing digital twins requires extensive time and coding expertise; however, Basetwo is a low-code AI platform that enables its users to deploy robust process control with ease, making it a premium choice for a manufacturing quality control system.

Features

Basetwo offers a comprehensive suite to enhance quality control in the manufacturing space. Some of its key features include:

- Easy data ingestion and cleaning from commonly used sources like OSI-PI

- User-friendly drag-and-drop interfaces for creating AI, mechanistic, or hybrid models

- Enables rigorous testing and validation of models for reliable deployment

- Built-in dynamic optimization and process control recommendations

- Empower teams to find optimal control points and conduct in-silico experiments

Pros:

- User-friendly platform catering to both engineers and data scientists.

- Hybrid modeling capabilities combine multiple technologies, such as traditional machine learning and mechanistic models.

- Customizable model builder and ready-to-use templates that adapt to diverse requirements.

- Anomaly detection to ensure product quality and operational reliability.

- Low OEM dependence with a high degree of customization.

- The cloud-based solution can be deployed in an online environment for real-time optimization.

Cons

- It may not be the most ideal solution for organizations seeking traditional Quality Management Systems (QMS) due to the focus on simulation and optimization

Target industries and customers

Designed for process engineers, the platform connects data science and engineering, promoting a collaborative atmosphere where expertise in both fields merges seamlessly.

Basetwo is the best option in process control for quality control, offering digital twin technology, a user-friendly interface, and affordable pricing. Its reputation with professionals, particularly in the oil and gas, pharmaceutical, manufacturing, and energy industries, has grown exponentially since its inception. It has several notable Fortune 500 clients, such as:

- Johnson and Johnson

- SIG Group

- Merck

- Chiyoda

- Boeing

Best for

Process engineers and data scientists aim to enhance productivity, quality, and efficiency through advanced process control and data science.

2. Minitab Statistical Software

Minitab Statistical Software stands out as a statistical analysis software known for its robust tools designed to enhance quality through data analysis. It is widely used in Six Sigma and quality improvement projects. However, Minitab Statistical Software functions primarily as a dedicated statistical tool, offering limited automation options and real-time data-driven decision-making capabilities.

Features

- Statistical analysis and hypothesis testing

- Data visualization tools

- Process control charts

- Regression analysis

- Designed experiments

Pros

- User-friendly interface

- Extensive statistical analysis capabilities

- Excellent for quality improvement projects

Cons

- Limited support for advanced machine learning

- General statistics software requires additional tools to address specific manufacturing needs for quality control

- Limited automation and integration options

- High cost of ownership for small businesses

Target industries and customers

Minitab has 40 years of global experience across various manufacturing, automotive, pharmaceutical, food services, and retail sectors. The notable customer base involves:

- Pfizer

- Gillette

- Ford Motor

- Honda Motor

- McDonald's

- Starbucks

- Panasonic

Best for

Manufacturers are seeking robust statistical analysis tools for quality control and process improvement.

3. JMP

JMP provides advanced data visualization and statistical analysis tools, making it suitable for exploring and understanding complex manufacturing data. However, along with its steep learning curve, it also requires a high degree of customization for each use case

Features

- Interactive data exploration and visualization

- Advanced analytics capabilities, including reliability analysis and what-if analyses

- Predictive modeling and cross-validation to validate models more effectively

- Data mining through mixed models enables users to analyze data where multiple groups of variables are coordinated

Pros

- Complex data presented in a visual manner

- Suitable for both market research and manufacturing applications

- Flexible pricing plans start at $1200 per year for individual subscriptions

Cons

- Complicated for new users

- Requires additional customization for manufacturing-specific use cases

Target industries and customers

MP is powerful statistical software designed with scientists and engineers in mind. It is used in pharmaceuticals, biotech, research, academia, and various industrial sectors. Some of their customers include:

- HP Hood

- Riffyn

- Thermo Fisher Scientific

- Syngenta

- DuPont

- Hexion

Best for

Organizations with data-savvy teams are seeking in-depth data analysis and modeling capabilities.

4. Q-Das by Hexagon

Q-DAS, which stands for "Quality-Data Analysis System," is a software system primarily used for data management and analysis within manufacturing and quality control processes. This software empowers organizations to proficiently collect, analyze, visualize, and manage quality-related data.

However, its integration with legacy systems is limited, its optimization features could be improved, and it is costly compared to its peers.

Features

- Data collection from various integrations and measuring devices, enhancing data accuracy and minimizing the risk of errors

- Statistical analysis and process control for quality improvement and reducing variations

- Visualization of quality data for a better understanding of complex datasets

- Reporting and documentation for easier collaboration and compliance with regulations

Figure 11: Q-Das workflow

Pros

- Q-Das specializes in quality data management, ensuring ease of mapping and visualizing data

- It offers integration with measurement devices

- It has comprehensive reporting capabilities

- Hexagon provides global customer support

Cons

- Offers limited automation and optimization features

- Limited integration capabilities within existing company tech stacks and legacy systems

Target industries and customers

Q-Das was founded in 1988 and was acquired by Hexagon in 2015, becoming a part of Hexagon Manufacturing Intelligence. Its customer base includes the following corporations:

- INNOVATEST Europe BV

- Mitutoyo America Corporation

- Balance Technology Inc.

- ACCRETECH (Tokyo Seimitsu Co., Ltd.)

Best for

Companies with a strong focus on quality data management, quality control, and supplier quality management.

5. Tulip

Tulip is a manufacturing software that enables manufacturing companies to create custom apps, enhance shop floor operations, and identify areas for improvement through digital workflows and quality control measures. However, utilizing the full benefits of Tulip requires substantial hardware upgrades, and it provides limited tools for statistical process control.

Features

- Custom app creation for manufacturing processes

- Ability to create real-time dashboards and reports from production data

- Process visualization and control

- Automation capabilities for machine downtime alerts, scheduled tasks, system integrations, and more

- Quality checks and validation

Figure 12.1: Tulip’s dashboard for real-time visibility of machines

Pros

- Tulip offers a free trial for new users

- Tulip has a mobile app for iPhone and Android for easier control

- A versatile product for various manufacturing processes

- Tulip is a GxP-Ready Platform, simplifying GxP compliance for manufacturers

Cons

- Requires customization and hardware requirements to fit specific manufacturing needs

- Inadequate statistical analysis and quality control tools

Target industries and customers

The versatile platform offers solutions to various industries, including electronics, automotive, industrial products, food and beverage, life sciences, additive manufacturing, machining, supply chain, etc. Some of their clients include:

- Chefsteps

- Piaggio Fast Forward (PFF)

- DMG Mori

- Staymobile

- Mack Molding

Best for

Manufacturing businesses that want to create customized apps for shop floor operations, quality checks, and process control.

Comparison Table

Conclusion

Upon evaluating the leading 5 quality control software solutions for manufacturing, each presents distinctive features tailored to various business needs and sizes.

Basetwo emerges as the top solution for quality control through process optimization. Due to its user-friendly interface, advanced modeling capabilities, and robust data integration, it offers a streamlined approach to process visualization and control.

Its low-code interface, customizable models, live simulation analysis of quality processes, and generative AI make it an ideal solution for enhancing manufacturing productivity and quality control.

Basetwo has a proven track record with Fortune 500 countries and has helped them reduce operating costs, energy consumption, and process deviations.

Figure 14: Basetwo's success story

Are you ierested in learning how Basetwo can optimize your company's quality control and quality management processes? Click here to book your free demo.

.png)

.png)

.svg)